Will there be fit for purpose substrates also in the future?

Arjan Zwinkels

The world is facing a great demand for substrates in the future. According to Arjan Zwinkels, Product Development Manager at Kekkilä-BVB, a significant part of the demand will still be peat.

- Peat will still be important in the future, partly for its safe and buffering features, partly because of the great amount of substrate needed in the future, Arjan says.

According to Arjan, it is estimated that the world will use twice as much peat in the future as is used today. Peat is safe, it buffers water and it is free from pesticides and bad fungi. It is also very safe for the grower; it holds the right amount of water.

- Peat is free from nutrients and can easily be mixed with other sustainable raw materials or organic fertilizers, Arjan says.

Peat as a base in mixtures is the future

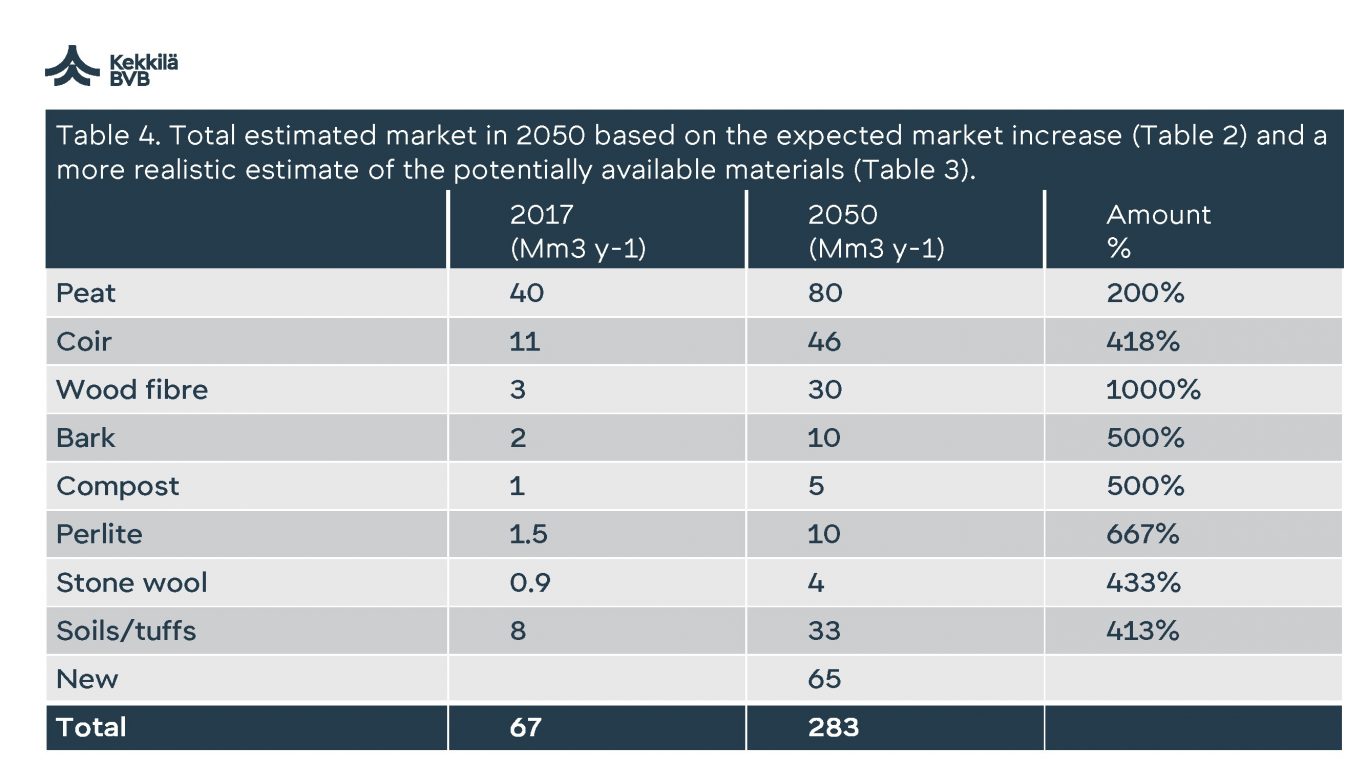

Due to the great amount of substrate required in the future, the need for new raw materials will also increase. The use of wood fiber, bark, coir, compost, perlite and sphagnum moss will also rise. The growing media constitute today at Kekkilä-BVB is peat complemented with perlite, coir and wood fiber. In the future it will be 40%-50% peat mixed with different kinds of existing or new materials.

– Peat as a base in mixtures will remain due to it´s capacity of being safe and have the capability to buffer water, nutrients and pH, Arjan says.

Offering new mixes of growing media raises the demand for advice on ´how to grow in new materials´.

- Growers need to know how to grow in new materials, we can support them with that knowledge, Arjan says.

Wood fiber, sphagnum moss and bark are renewable, sustainable raw materials. While peat has a higher carbon footprint, coir has a higher water footprint due to the washing process.

- You also have to buffer coir with calcium and then you have to transport it, nor does coir buffer as much water as peat either, Arjan says.

Responsible Produced Peat – RPP certification

Swedish, Finnish and Estonian country specific legislations regarding peat harvesting are very strict and harvesting is done in accordance with local regulations. On top of these legislations we proceed with RPP certification. When harvesting, peat is harvested from degraded areas, areas that have been drained by earlier generations. Harvesting is nowadays never done in untouched peat bogs. RPP certification ensures that peatland will be used and managed during and after harvesting in a responsible way.

The RPP certification system does not allow peat extraction from high conservation value areas.

The system stimulates peat extraction from highly degraded areas followed up by appropriate after-use measures. It also implies leaving all ecologically valuable areas, with or without a nature conservation status, undisturbed. Responsibly Produced Peat certification secures the best possible development after completion of peat production, the preference being restoration.

Read more about peat harvesting and afterlife concept here.

For more information please contact Arjan Zwinkels.