At Kekkilä-BVB we do our business in balance with nature. It is not an easy task, because we need land, materials, water and energy for almost everything we do. But every year we get a step closer to reduce our greenhouse gas emissions, increase circularity and enhance biodiversity. Within our own operations these focus areas are addressed through the implementation of our Green Factory concept.

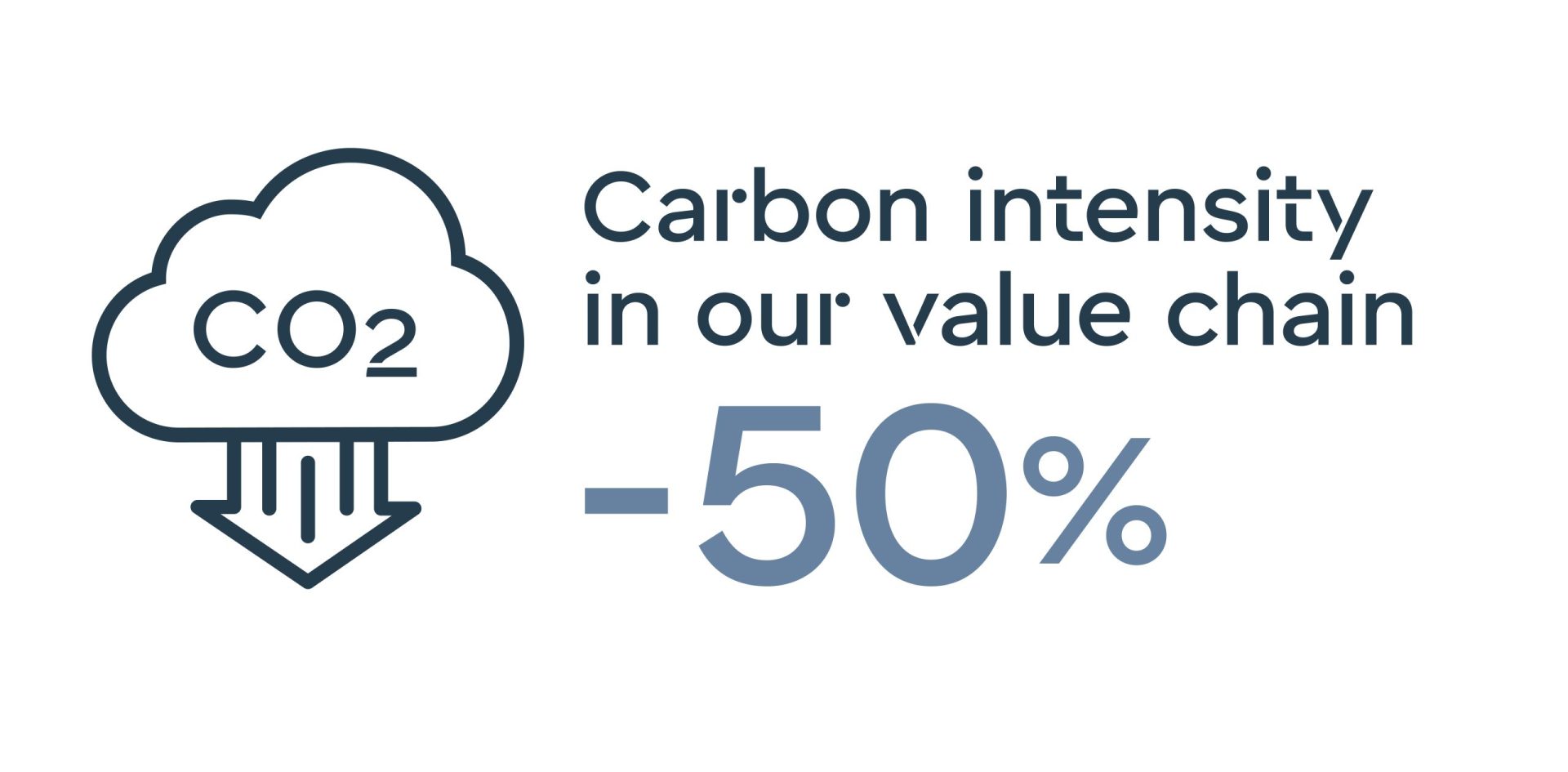

Together with our partners in the value chain we will cut the carbon intensity -50% by 2030. We are aiming at becoming carbon neutral by 2050.

Greenhouse gas emissions

When counting our carbon footprint, we take the whole value chain into account. We have assessed our carbon footprint of the whole supply chain according to GHG Protocol.

The largest share of emissions is caused by the use of electricity. In addition the indirect emissions come from horticulture peat. We have set forth in developing our strategy to reduce our emissions in the value chain.

As part of our Green Factory concept we are moving towards renewable electricity for all our operations in 2025, which will reduce our own footprint significantly. We will eventually replace oil heating with ground source heat or geothermal heat in Finland and Estonia factories.

We are also aiming to use more and more renewable fuels in our operations. One way to reduce the emission coming from logistics is to focus on local sourcing of materials and setting minimum thresholds on amounts to be shipped.

We are taking actions:

- As part of our Green Factory concept we have decided to move towards renewable electricity for all our operations in 2025, which will reduce our own footprint significantly.

- During 2022 we are conducting several evaluations for replacing oil heating with ground source heat or geothermal heat in Finland and Estonia factories.

- In order to improve our logistical emissions we are focusing on local sourcing of materials and setting minimum thresholds on amounts to be shipped.

- We challenge peat suppliers to look for ways to reduce the emissions during excavation and after use; for example using a mass transfer method in peat harvesting. Peat is currently a vital material for the growing media industry and it is the most safe, versatile, effective and clean material for growing. And if not for its carbon footprint it would be the most environmentally friendly too.

Peat is a vital raw material for the growing media

Another topic much talked by the whole sector are emissions from peat extraction, which has the biggest impact on our overall greenhouse gas emissions. We are challenging our suppliers to look for ways to reduce the emissions during excavation and after use.

Peat is currently a vital material for the growing media industry and is the most safe, versatile, effective and clean material for growing. And if not for its carbon footprint it would be the most environmentally friendly too.

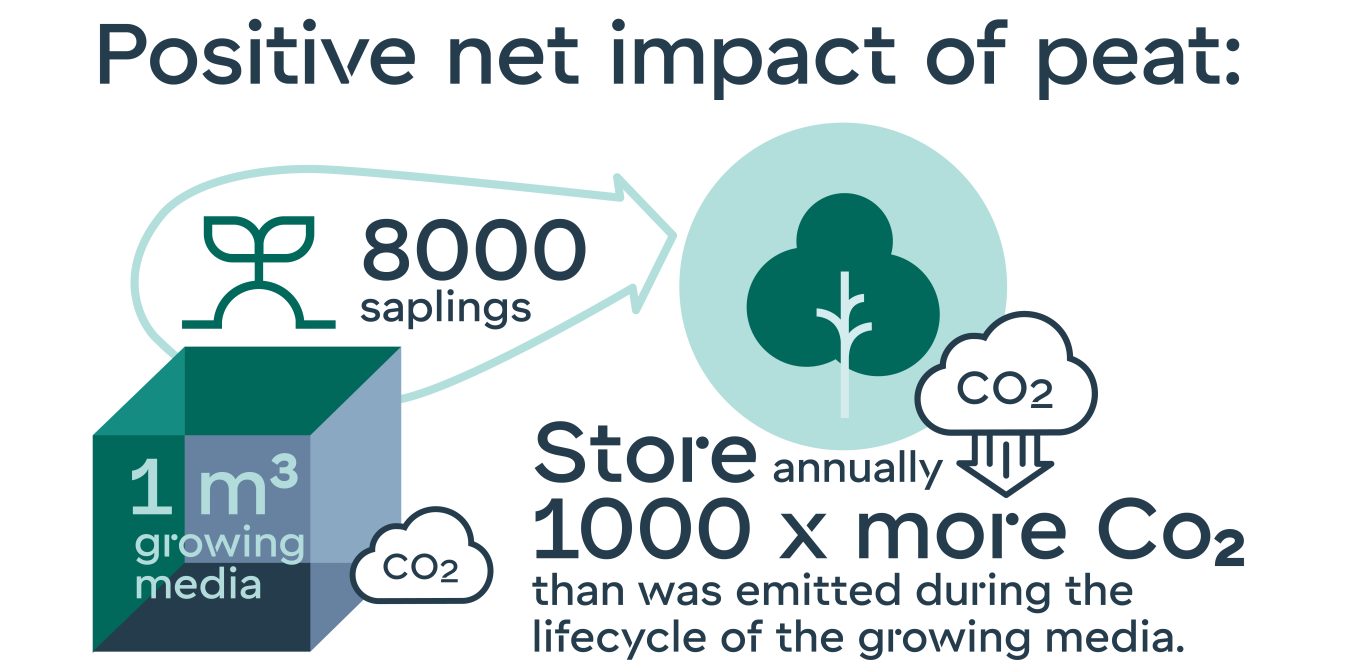

Gardening and landscaping are creating positive net impact

It is important to look at the positive net impact we have with our growing media solutions when calculating carbon footprint. Especially when it comes to gardening and landscaping, the carbon footprint of the growing media itself is negligible compared to the plants, shrubs and trees that are grown in it.

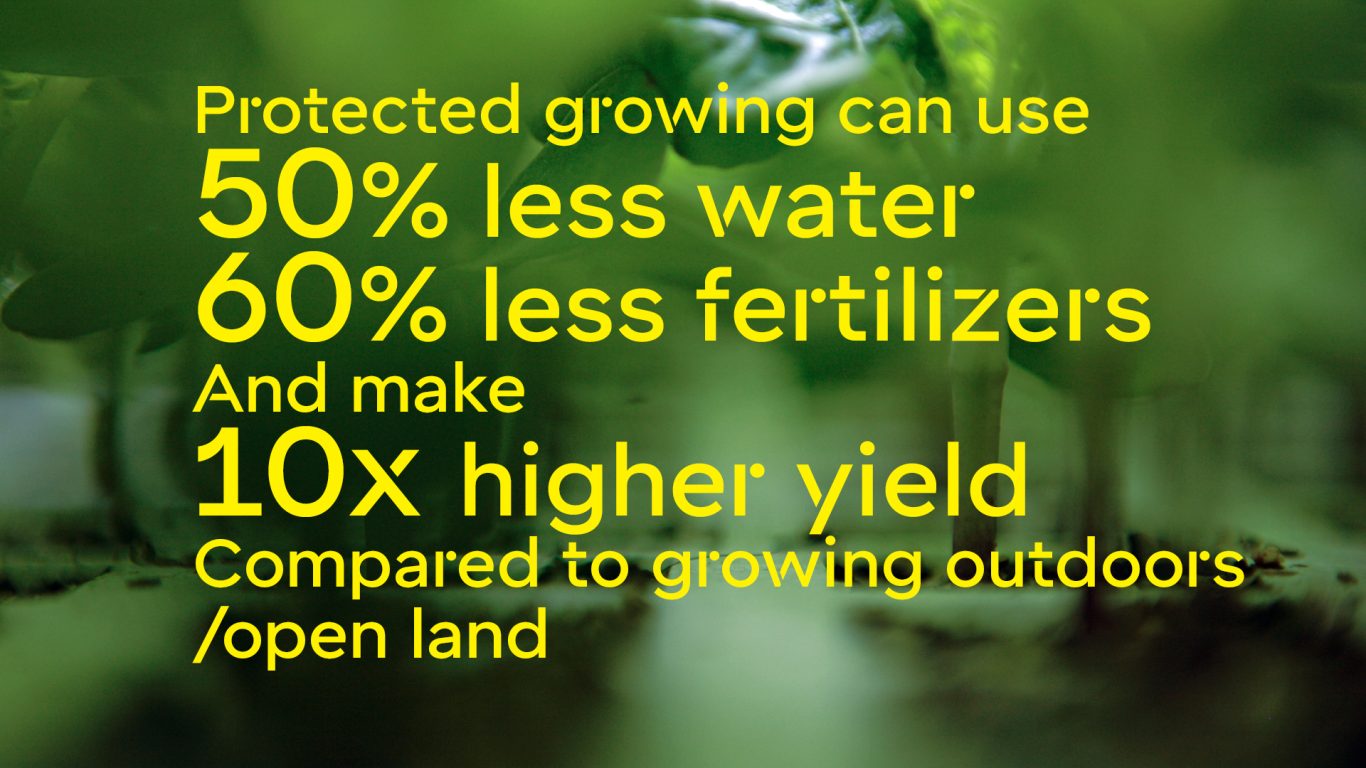

Taking the whole value chain into account

In professional growing protected environments yields can be up to 10 times higher than in open field growing. This means that land can be made available for growing trees for carbon storage. Also it is possible to reduce the use of fertilisers with 60% as well as the related CO2 emissions. And through protected growing, extreme weather, soil pollution or other events can’t cause crop losses, which would be a waste of energy, water, fertilisers and labour. That’s also why in our search for the most sustainable growing media we take the impact of the whole value chain into account, otherwise we will end up with suboptimal solutions.

Following the standards

In improving the quality and environmental performance of our operations we are following standards such as the ISO 9001 and ISO 14001 certifications. The ISO 9001 covers all Kekkilä-BVB sites. Moving on, we will continue to implement the ISO 14001 to the Netherlands sites.

Follow the progress of our goals

Greenhouse gas emissions |

|||||||

| Reduction of CO2 footprint of operations (scope 1+2) (ktCO2-eqv.) | |||||||

2020 |

2021 |

2022 |

2023 |

2024 |

2025 |

2030 |

|

10.3

|

-1% |

-17% |

-4% |

-43% |

-50% |

-50% |

|

Greenhouse gas emissions |

|||||||

| CO2 footprint of operations (scope 1+2+3) (tCO2/M€) | |||||||

2020 |

2021 |

2022 |

2023 |

2024 |

2025 |

2030 |

|

3.0**

|

-1% |

-25%** |

-31% |

-29% |

-25% |

-50% |

|

Circularity |

|||||||

| Volume of circular raw materials (Mm3)* | |||||||

2020 |

2021 |

2022 |

2023 |

2024 |

2025 |

2030 |

|

1.2 |

1.5 |

1.4** |

1.4 |

1.4 |

1.4 |

2.0 |

|

Circularity |

|||||||

| Use of recycled materials in packaging | |||||||

2020 |

2021 |

2022 |

2023 |

2024 |

2025 |

2030 |

|

19% |

29% |

31% |

37% |

34% |

50% |

80% |

|

Circularity |

|||||||

| Recycling rate of waste in own operations | |||||||

2020 |

2021 |

2022 |

2023 |

2024 |

2025 |

2030 |

|

59% |

66% |

85% |

64% |

34% |

90% |

100% |

|

Biodiversity |

|||||||

| Share of certified responsibly produced peat in own products | |||||||

2020 |

2021 |

2022 |

2023 |

2024 |

2025 |

2030 |

|

21% |

48% |

57% |

64% |

83% |

80% |

100% |

|

* Circular raw materials definition: Raw materials that are from a renewable source or are given a second life after their first use, like compost from garden waste.

** This year we have started to include our activities in Germany in our sustainability performance. Historical performance and the base year performance have also been corrected